HD1963MM2pam

A Look at Minuteman Program

As associate prime contractor for

guidance and control equipment for the MINUTEMAN ICBM, North American

Aviation's Autonetics Division designed, developed, and is producing virtually

all missile avionics. Autonetics

systems integrated into MINUTEMAN for guidance and control comprise 99% of all

electronics in the missile (except for the reentry vehicle). In addition to airborne systems, the

division provides supporting aerospace automatic ground checkout and alinement

equipment.

In

fulfilling requirements of the MINUTEMAN I Program, Autonetics has met or

surpassed goals of reliability, accuracy, and weight. Of the more than 25,000 components in its systems within each

missile, over 98% achieved reliability improvement by a factor of 100 to 1. The

program has established a record for the shortest development time from design

to operation of any ballistic missile.

Technological requirements of the

Ballistic Systems Division of the U.S. Air Force for the MINUTEMAN I missile

were unprecedented at the outset of the program. The missile required a degree of reliability previously

considered impossible. Design

parameters called for extreme accuracy, storability, productivity, and low

cost. The guidance and control systems

were to be self-contained, jam-proof, and non-radiating. The requirement to fire from an underground

silo in less than 60 seconds demanded subsystems and components of such

long-term reliability that they could be left running for years without failure

ready at any moment for launch to a target more than 6000 miles away.

To meet the challenge, Autonetics

applied a concept of system simplification for the avionics design, and

initiated a rigorous program of reliability improvement for components and

systems. New engineering techniques and

production methods were introduced, together with innovations in cost reduction

and control. A separate MINUTEMAN

Division was established to coordinate the activities of Autonetics, and of 35

major subcontractors and 3200 suppliers covering 40 states.

The overall technical key was

integration-integration of Autonetics technical resources into the MINUTEMAN

Division; and integration of multiple subsystems into a simplified, automatic,

digital computer-controlled system which operates unattended.

Delivery was made of two complete

wings the first year. The 300th

unit-targeted for November 15, 1963 was delivered October 23, 1963. In August of 1964, the 1000th MINUTEMAN guidance

system was delivered.

During the past 3 years of the

MINUTEMAN I Program, Autonetics has held costs below the Ballistic Systems Division ceiling and/or target.

A look at Minuteman Scoreboard:

RELIABILITY

Guidance and

Control (G&C)

Wing I: 70% higher than contract

objective

Wing

II-V: 60% higher than contract objective

(Wing II-V objective was 110% higher

than Wing I objective)

Flight

Control

Wing

I: 900% higher than contract objective

Wing

II-V: 360% higher than contract

objective

(Wing II-V objective was 200% higher

than Wing I objective)

Operational

Ground Equipment

Wing I: 66% higher than contract

objective

Wing

II-V: 89% higher than contract objective

(Wing II-V objective was 135% higher

than Wing I objective)

WEIGHT

Airborne

Systems

15%

below contract objective

ACCURACY

30%

better than contract objective

FLIGHT TEST

PROGRAM

Eastern Test

Range (Cape Kennedy)

In 40 months: 53 Flights; 49 G&C

Successes

Last

20 months: 35 Flights; No primary G&C failure

Western Test

Range (Vandenberg AFB)

In

22 Months: 60 Flights; 57 G&C Successes

First

15 Months: 25 Flights; No primary

G&C failure

EQUIPMENT

DELIVERED

R&D 1,103 Pieces of End Item

Equipment

Production 5,254 Pieces of End Item Equipment

16,357 Total

in 34 Months

At

Present 3 5 Major End Items shipped

per working day

MINUTEMAN I

DELIVERY

PERFORMANCE

Ahead

of accelerated contract schedule

SITE

OPERATION

In

less than 22 months:

4

Complete Wings 600 Operational Sites

Over

6.4 million Gyro Operational Hours

Over

9.6 million Velocity Meter Operational Hours

PARTS

OPERATION

Silo

25,505 Electronic Parts per silo

Over 60 billion Operational Parts

Hours

Airborne

20,440 G&C Electronic Pprts per

missile

Over 46 billion Operational Parts

Hours

SPARES

DELIVERED

Over 24,000 Line Items

Over

800,000 Parts

TRAINING

Over

500,000 Conducted Student Hours

A Look at MINUTEMAN II

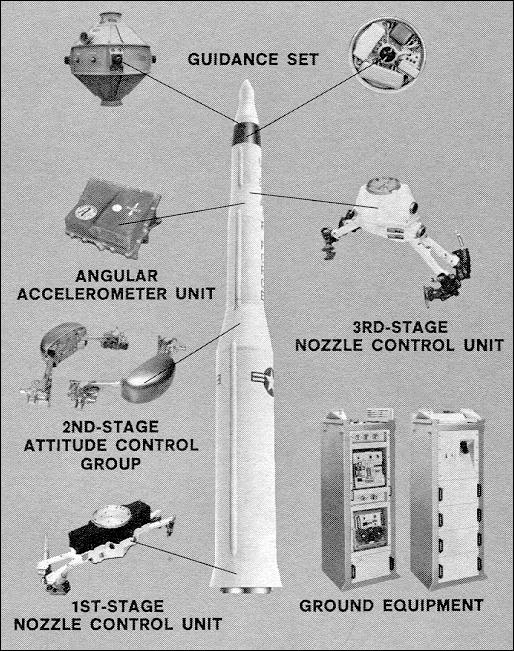

AUTONETICS SYSTEMS FUNCTIONS IN

MINUTEMAN II

Autonetics' new guidance and control

system plays an expanded role in the MINUTEMAN II Weapon System, contributing

substantially to the missile's increased range, accuracy, reliability, and

strategic flexibility.

The heart of the system is an

extremely fast, lightweight, microminiaturized D37 digital computer with a

memory capable of storing a complete ground and airborne operational program,

including all target data required for guidance to one of a number of stored

targets. The desired target is selected

remotely from a launch control center prior to missile launch.

PRELAUNCH: The computer, with the aid of Autonetics aerospace ground

equipment, sequences the guidance and control system through alinement, test,

calibration, and targeting modes into a strategic operating mode. During the strategic mode, the computer

automatically decodes, processes, and executes commands from the launch control

center for test, calibration, and targeting, and in addition continually

monitors and reports missile and support equipment go/nogo status to the

control center.

LAUNCH: When commanded to launch, the computer controls complete

countdown in less than a minute in conjunction with the support equipment. Countdown includes complete testing of the

missile system, activation of the missile battery power supplies, arming of the

missile ordnance devices, initiation of flight program, and igniting of

first-stage motor.

FLIGHT

After ignition of the first stage, the computer processes missile attitude,

attitude rate, and velocity information from stable platform position pickoffs,

downstage angular accelerometers, and platform accelerometers, to solve

guidance, steering, and control equations.

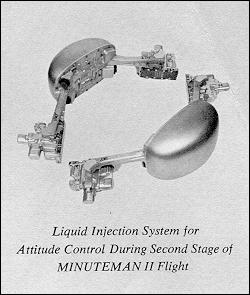

Moveable nozzles on first and third stages, and liquid injection on

second stage, control the direction of thrust for missile steering. Nozzle movements and liquid injection are

commanded by the computer and mechanized by the flight control system. The computer also generates signals for

staging, third stage thrust termination, and warhead pre-arming, as well as

re-entry vehicle separation, retro-rocket firing, and penetration aids

dispersal. Pre-arming of the warhead

follows flight safety checks made during final moments of powered flight.

A Look at...

ADVANCES

IN MINUTEMAN II ELECTRONIC SYSTEMS THROUGH USE OF MICROELECTRONICS

Technical advances by Autoneties in

microelectronics are being incorporated into the MINUTEMAN 11, to achieve even

greater dependability of the missile, increased system flexibility, lighter

weight for extended range, and ultimately lower cost. For this improved version of the missile, Autoneties developed

the first microelectronic equipment ever pro. vided for a major defense

program.

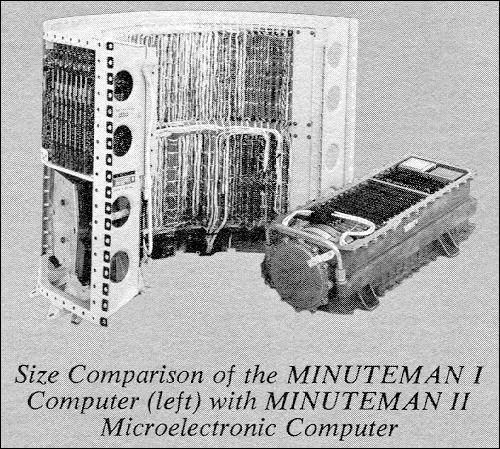

COMPUTER

ADVANCES: Autonetics' D 37 computer in

MINUTEMAN II is the first military production-designed microelectronic

computer. Size of the D37 is one-fourth

that of its D17 predecessor in MINUTEMAN I. Weight has been reduced by

one-half, and power requirements are one-half.

Memory capacity has increased by 2 1/2 times. The power supply has been incorporated into the computer. In addition, many of the previous ground

checkout equipment functions are performed by the new microelectronic computer.

The D37 is mechanized by integrated

circuits. Multilayer circuit boards, on

which the microelectronic circuits are mounted, provide for high packing

densities, improve the interconnection techniques, and permit easy maintenance.

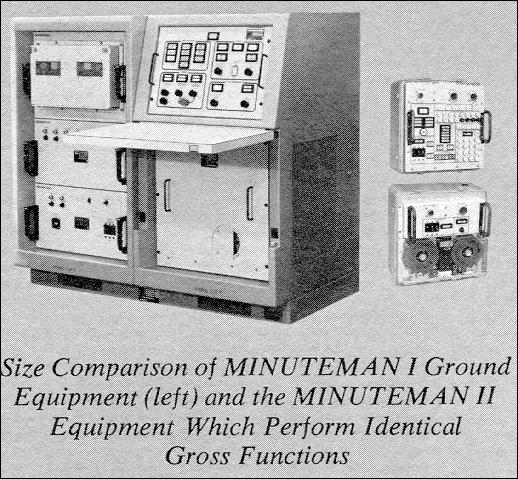

GROUND

EQUIPMENT ADVANCES: Use of

microelectronic circuits has reduced both size and weight of MINUTEMAN ground

equipment and increased its operational flexibility. Equipment for MINUTEMAN I, which consisted of a two-bay console

housed in a targeting van, has been miniaturized to the size of two small

suitcases for MINUTEMAN II. Weight has

dropped from 950 lb to 90 lb – or to just 45-lb one-man carry" weight for

each of the two suitcases.

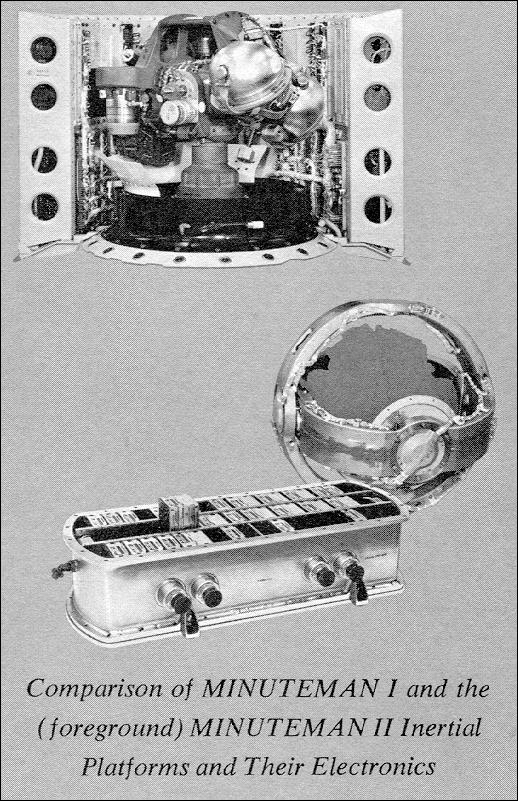

INERTIAL PLATFORM ADVANCES: The MINUTEMAN II uses a three-axis,

gyro-stabilized platform which mounts three pendulous integrating gyro

accelerometers and a gyrocompass azimuth assembly. The platform includes extensive microelectronics and is of

conventional external-gimbal design with beryllium gimbals and a beryllium

stable element. Ruggedness and extreme

rigidity are primary characteristics.

The stable platform is mounted

within a pressurized housing which contains a water-to-gas heat exchanger for

precise temperature control.

FLIGHT

CONTROL ADVANCES: Microelectronics

incorporated into Autonetics' flight control subsystem in the MINUTEMAN II

contributes to the missile's lighter weight, increased reliability, and reduced

field maintenance costs.

The use of integrated circuits and

microminiaturized components allows the major portion of flight control

electronics to be packaged into a single unit and moved upstage into the

guidance and control package of MINUTEMAN II.

Because this guidance and control section can be replaced in the silo

without removing the missile, field maintenance has been considerably

simplified.

A new attitude control group

(secondary injection system) with microelectronic components governs injection

of liquid Freon to the second stage nozzle control unit.